Smart engineering for innovative composite machinery

Composite machinery is Dutch craftsmanship, serving customers worldwide

Composite Machinery B.V. is an innovative, pragmatic Dutch company that offers very competitive prices on composite machinery solutions for filament winding and pultrusion production lines.

With our expertise and knowledge of the international composite market, we help you optimize the performance and efficiency of your new production line. Our company specializes in constructing and supplying a wide range of well-functioning equipment, from standard to fully customized machinery, all reliable and easy to maintain.

We prioritize building strong relationships with our customers based on trust. Our team works closely with customers to provide outstanding service, comprehensive business cases and innovative solutions that support your growth and success.

We engineer, produce and install machines equipped with high-quality European brand components, like Siemens, Wittenstein and SKF.

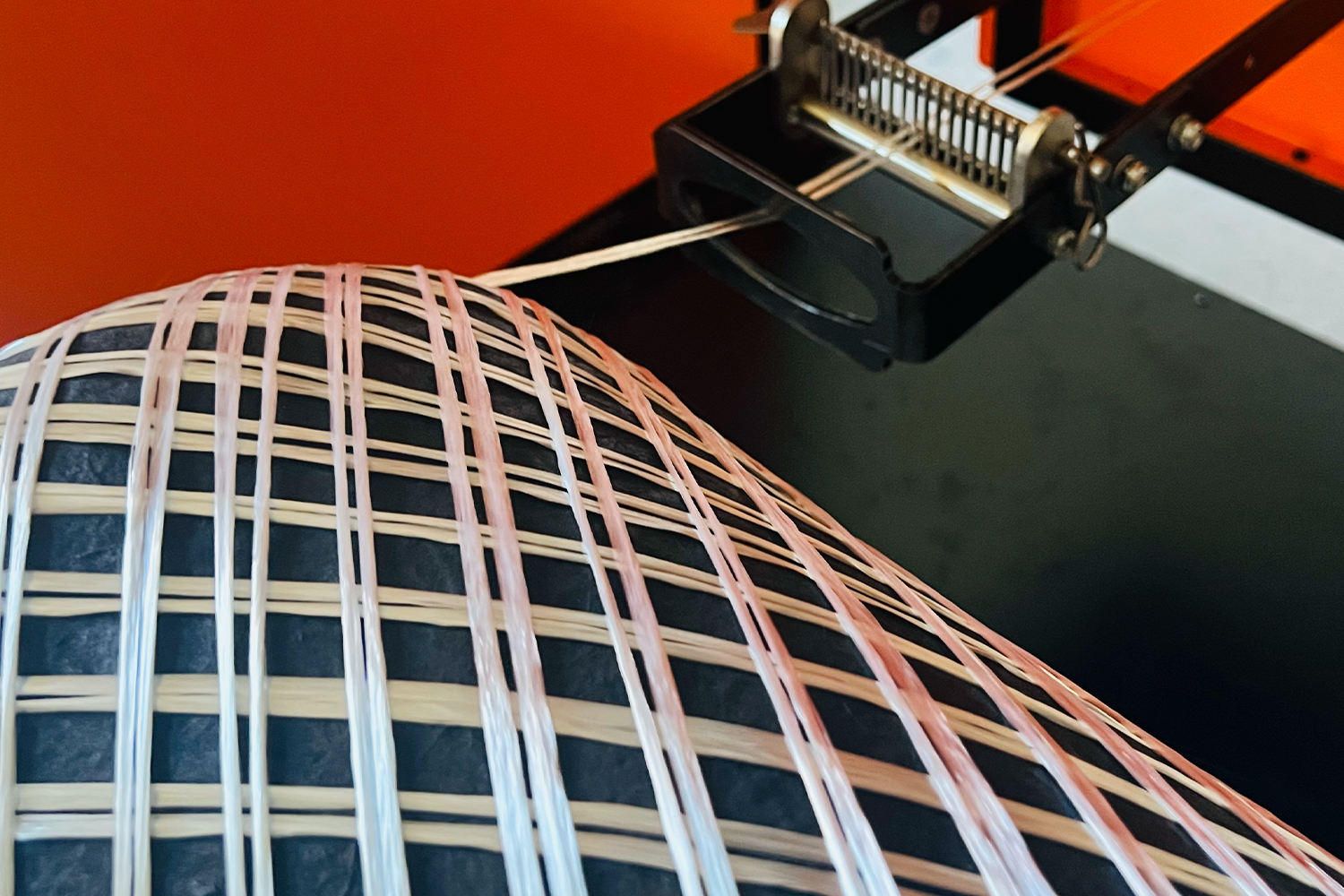

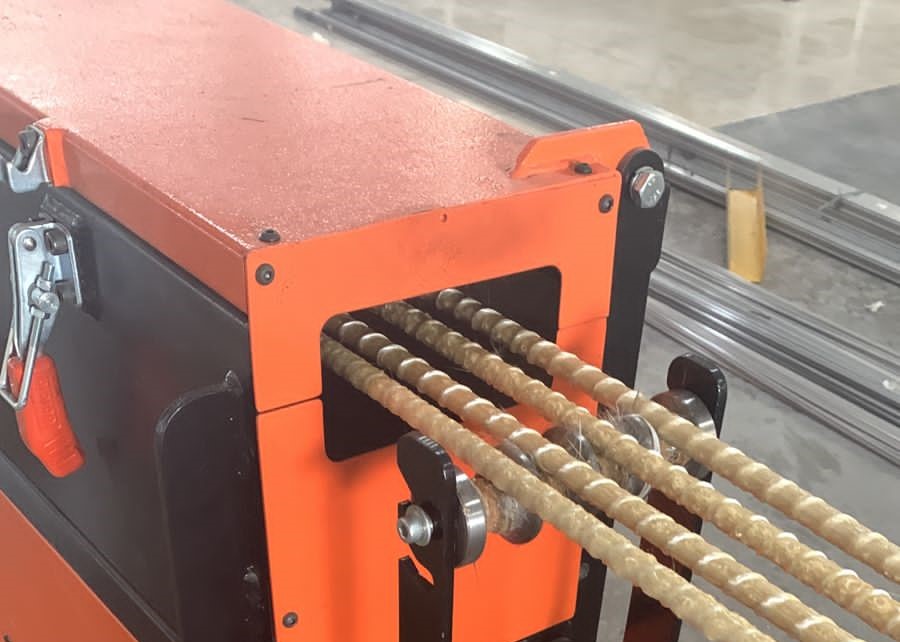

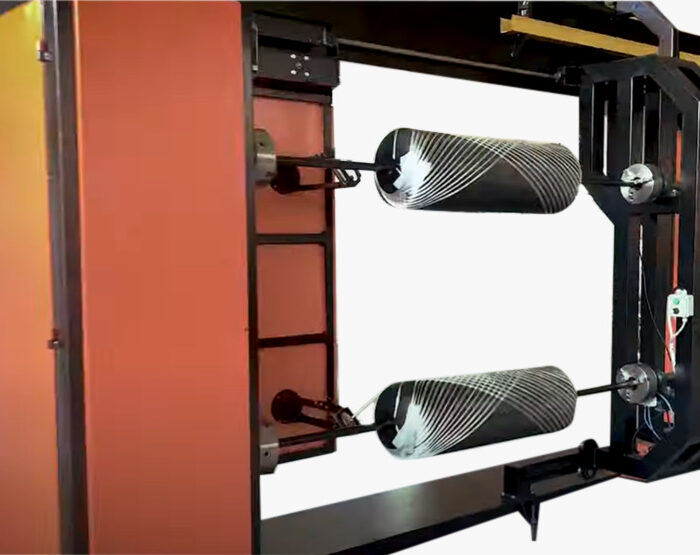

Production process of Filament winding

Latest news & events

Collaborating partners

Let's work together

Fill in this contactform and we will contact you!