Filament winding

Filament Winding

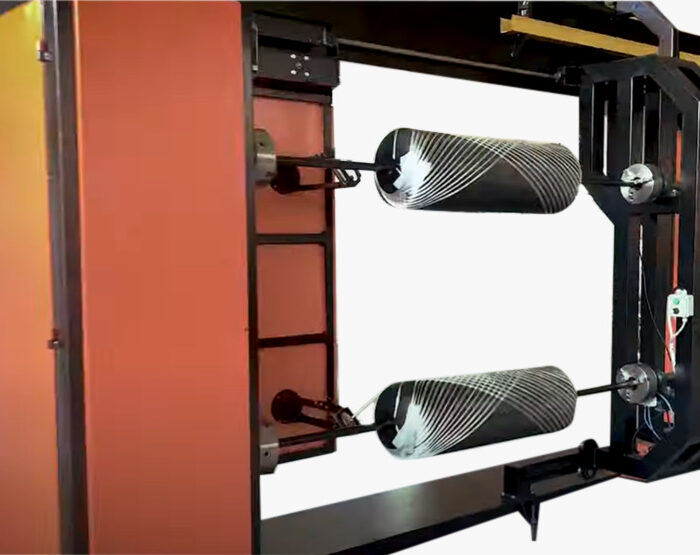

Our filament winding technology offers remarkable benefits for the efficient production of high-quality composite materials, featuring advanced capabilities in wet filament winding. These systems automate the winding of carbon and glass fibers onto mandrels, ensuring precision and quality for applications in aerospace, automotive, and infrastructure.

The Key Benefits Of Our Filament Winding Machines

Our composite filament winding machines offer numerous advantages that distinguish them in the marketplace. Filament winding is a key manufacturing process in the composites industry, where fibers such as carbon, glass or basalt are automatically wound onto a rotating mandrel to create cylindrical or square products like pressure vessels, pipes, poles and beams. The result is a stronger, lighter-than-steel or aluminum, and corrosion-resistant composite product.

Precision engineering ensures that each product meets stringent quality standards, while the reliability of our equipment contributes to higher production rates with less downtime. Moreover, our machines are designed for customization, enabling manufacturers to adapt the technology to their specific requirements. This flexibility is essential for customers seeking to innovate and maintain a competitive edge in their respective industries. The filament winding composite market is currently experiencing robust yearly growth worldwide at a rate of 9%, particularly in producing countries like North and South America and Europe, making it a strategic time to invest in advanced composite manufacturing solutions.

Wet Filament Winding Efficiency

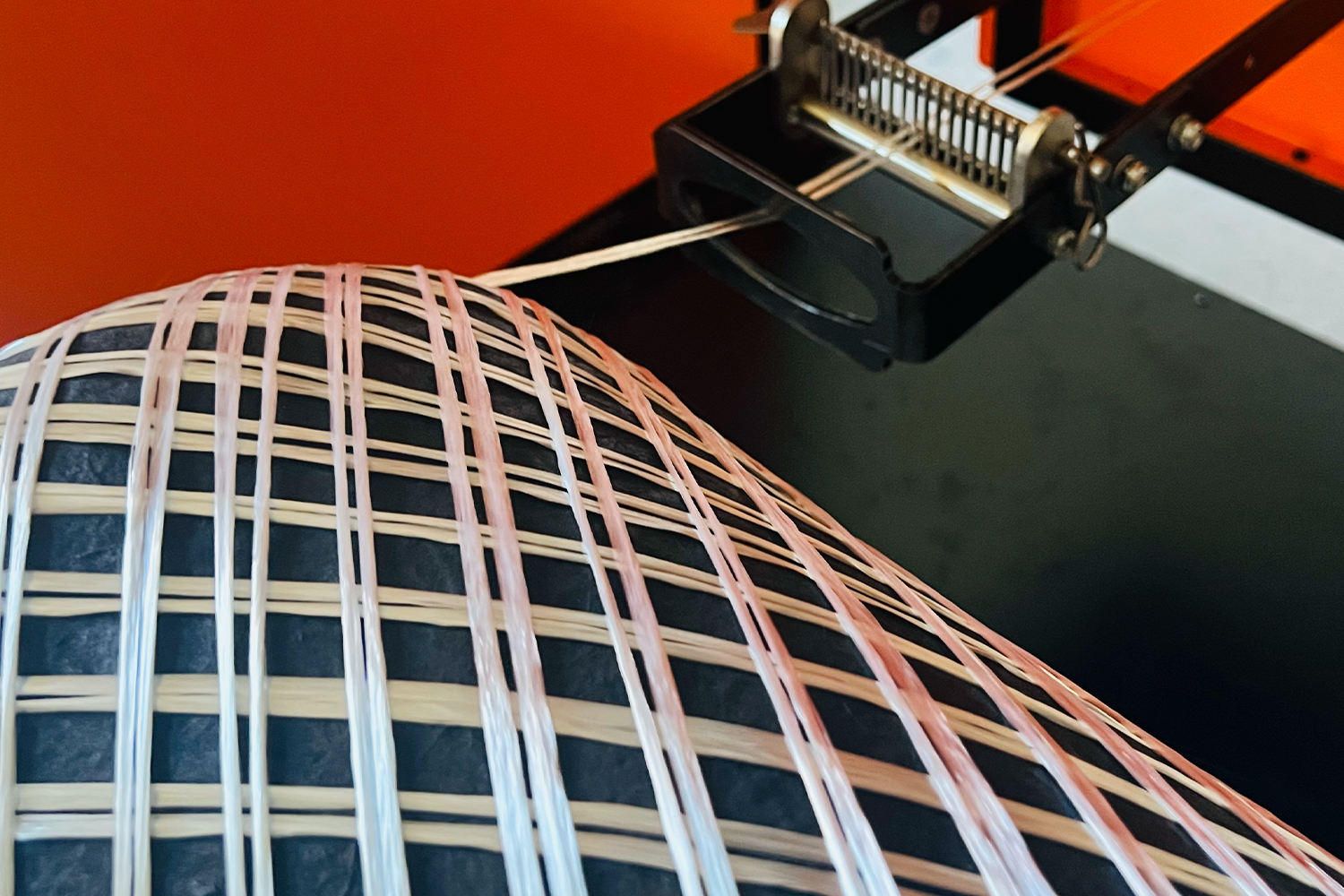

Compared to standard wet winding, the composite prepreg filament winding process offers superior resin distribution, ensuring bonding throughout the product. This method significantly improves the quality and consistency of the composite materials. It’s particularly effective for producing cylindrical components like high-pressure vessels and pressure pipes, where strength and precision are essential.

The efficiency of the prepreg filament winding process makes it a standout technique. Using towpreg fibers ensuring optimal impregnation and pre-curing fibers, resulting in advanced composite products. This method is not only clean but also allows up to three times faster winding than traditional wet winding techniques. With these faster production times and better resource utilization, our customers can meet the increasing demands of industries like aerospace, automotive, and infrastructure, all while maintaining top-tier performance standards.

Filament winding process

Let's work together

Fill in this contactform and we will contact you!