Applications

Your applications

Our filament winding production line is a discontinue process for automated production of composite constructions. This procedure includes winding resin-soaked fibers (filaments) around a rotating mandrel, to create cylindrical or tubular components. With this method our engineer design, build and install composite machinery used for producing composite pipes (for oil, gas, and water), high-pressure containers or tanks, utility poles (such as electricity and light poles) and antennas.

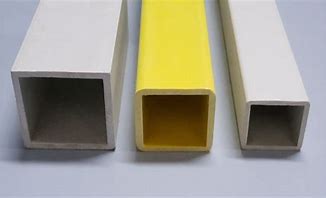

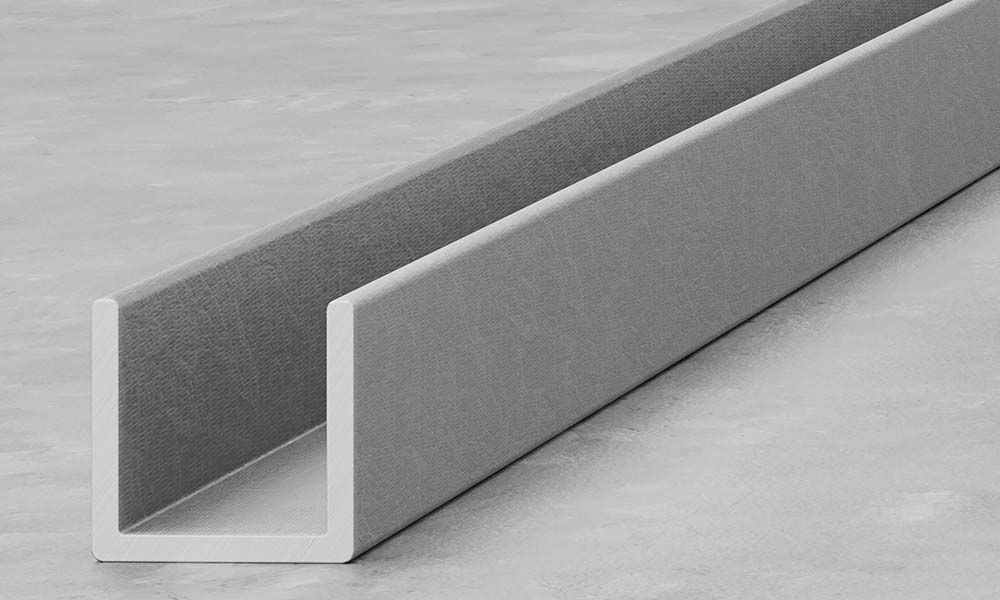

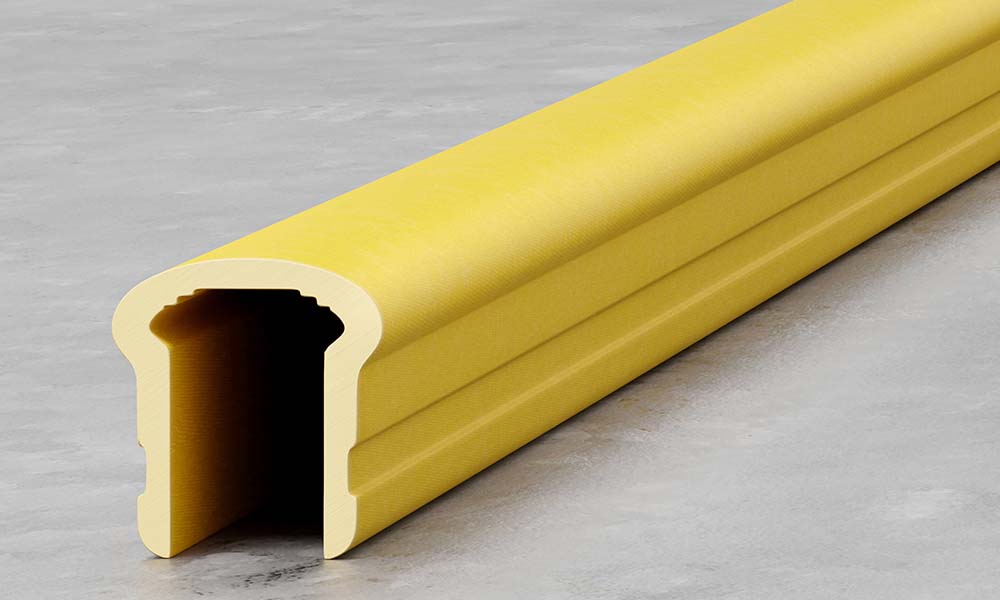

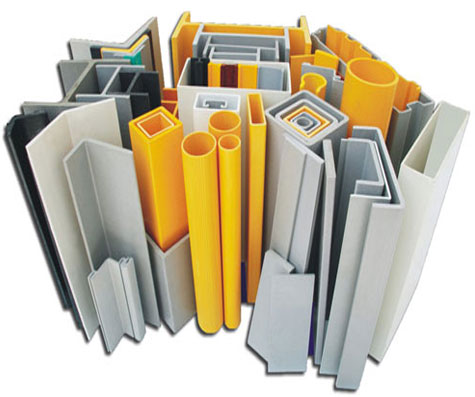

Our company specializes in the design, build and installation of composite machinery within the pultrusion process. By saturating fibers with resin and pulling them through a heated die, our clients are able to produce (continue process) durable composites that are widely used in industrial applications. Our machines are capable of producing a variety of products such as rebar, rebar mesh, profiles, tubes and poles.

In the world of construction, innovation is the key. And when it comes to reinforcing concrete structures, composite rebar has emerged as a game-changer.

Composite fiberglass poles (FRP fiber-reinforced polymer) are substitutes for traditional wood, steel, and concrete poles for utility and lighting projects.

Let's work together

Fill in this contactform and we will contact you!