Corrosion-resistant composite rebar

Composite rebar is the future of construction

Older concrete (underground) structures are experiencing increasing issues with concrete decay, as their steel components corrode due to water- or chemical infiltration. For example seaside constructions such as harbor quays that are exposed to salty seawater. This requires expensive and time-consuming maintenance due to the need for repairs, redesign, and conversion.

Composite rebar is the solution. We can offer you the composite rebar production line!

Many advantages of using composite rebar

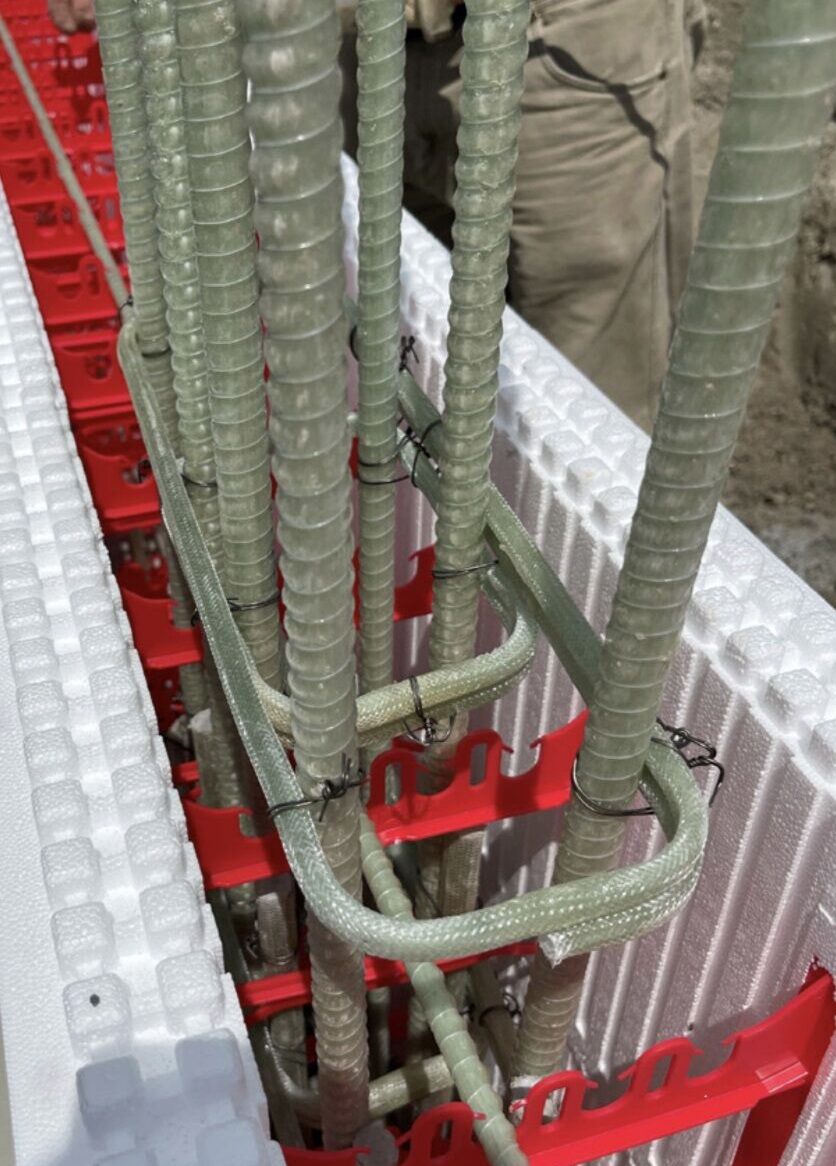

More customers across various industries are showing interest in and utilizing composite rebar solutions. Composite rebar has many advantages, including lightweight and corrosion resistance, high tensile strength (twice that of steel), and reduced embodied energy compared to steel. It is a promising solution for lasting and sustainable construction.

Infrastructure projects, such as the construction of new roads, ports, dams, tunnels, and railways, benefit from using composite rebar for its durability. This is especially important for projects where preservation is challenging and expensive.

Composite rebar is also immune to the effects of alkaline substances present in concrete, which can cause steel rebar to corrode. This means that structures reinforced with composite rebar maintain their integrity and strength over time, and are corrosion-resistant.

Benefits of composite rebar

- Weighs 25% of steel, easier to handle longer lengths

- Lower transport costs

- Reduced carbon footprint in construction projects

- Lower labor and equipment costs

- Comparable price to steel rebar

- Excellent thermal qualities (low thermal conductivity)

- Corrosion-resistant and long-lasting (up to 80 years)

- Twice as strong as steel

- Unlimited length (rolls) for easy transport on pallets

- Eliminates on-site welding

- No impact on electromagnetic fields (e.g., Wi-Fi)

- Resistant to temperature changes (-70°C to +200°C)

Case studies showcasing the success of composite rebar for the future

Composite rebar was used extensively in the construction of the metro line in Dubai, ensuring the durability and longevity of the structures in the city’s difficult climate. The lightweight nature of composite rebar also facilitated the construction process, leading to time and cost savings.

Another succesfull project was the Whitemud Drive Bridge in Edmonton, Canada. The bridge was reinforced with composite rebar, providing superior corrosion resistance in the cold Canadian winters. The lifespan of the bridge extended with the usage of composite rebar.

Save maintenance costs !

When choosing composite rebar for infrastructure projects. consider the return on investment (ROI). Composite rebar can save a lot on maintenance costs, due to its corrosion resistance and longer lifespan compared to steel. The CO2 footprint is also reduced, as more composite rebar can be transported per truckload, decreasing the number of trips needed. It is easy to produce composite rebar locally.

That’s why a composite rebar production line is interesting for your business!

Our production lines are easy to operate and flexible in terms of the thickness of the rebar. If you would like more information or a quote, request it here.

Let's work together

Fill in this contactform and we will contact you!