Products

Products

At Composite Machinery we can offer you the following products and machines that are used for making composite products such as pipes, poles and composite rebar. We can also offer you a quotation for our complete production lines, such as a pole production line.

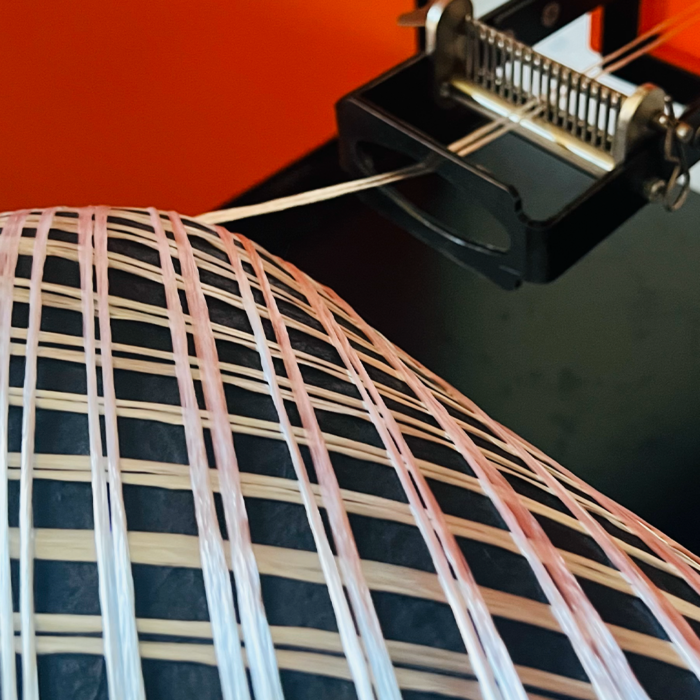

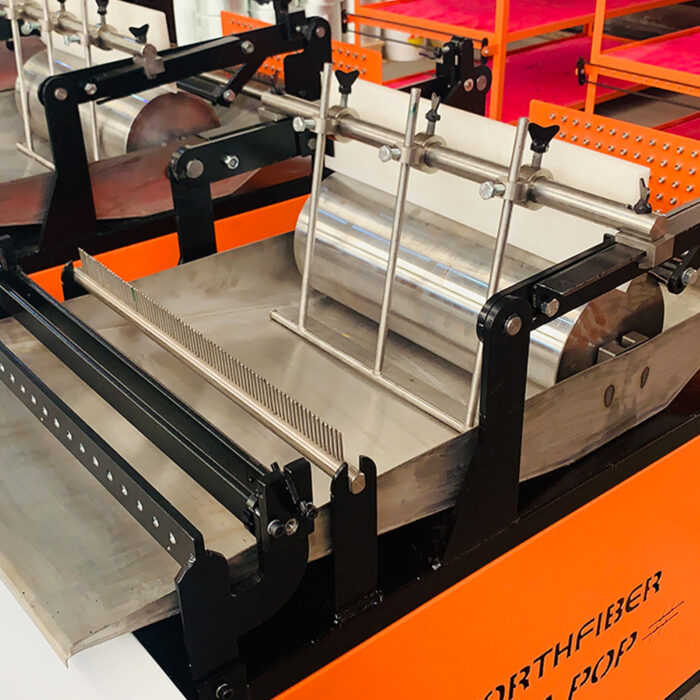

The filament winder is a system that can wind various composite products using fibers and resin. The fibers are wound in a specific pattern around a mandrel. This system is commonly used to create products like tanks, poles, tubes, and pipes.

The servo creel is a fiber tension system with integrated tension sensors to add compliance and allow very dynamic tension variations. The electronic-controlled tensioning system is suitable for high-end applications.

Our production lines are equipped with state-of-the-art resin-impregnation systems, ensuring that each fiber is thoroughly and optimally saturated for the best strength and durability.

We deliver a multifunctional extraction machine that is highly flexible and suitable for processing tube lengths up to 17m and mandrel diameters up to ø 800mm.

An oven is used to cure winded or pultruded products, mostly epoxy resin. It can be heated by infrared, gas, or electricity and the product can be turned while curing is needed.

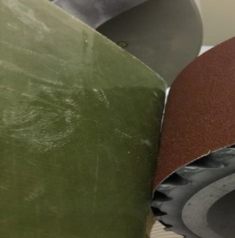

The sanding machine is a full CNC machine, equipped with a heavy duty sanding belt. The sanding belts grid can be selected based on your requirements and type of composite.

A gelling station rotates the mandrels while curing the winded products. The mandrels are placed on supports that keep them rotating to prevent sagging or dripping of excess resin and ensure a straight product.

The drilling system in a composite production line is designed to create precise holes or cut-outs in the cured composite profiles.

The cutting system we can offer you, is a crucial component that ensures the final composite product is trimmed to precise lengths after the curing.

Let’s work together

Fill in this contactform and we will contact you!