Filament winder

Filament winders

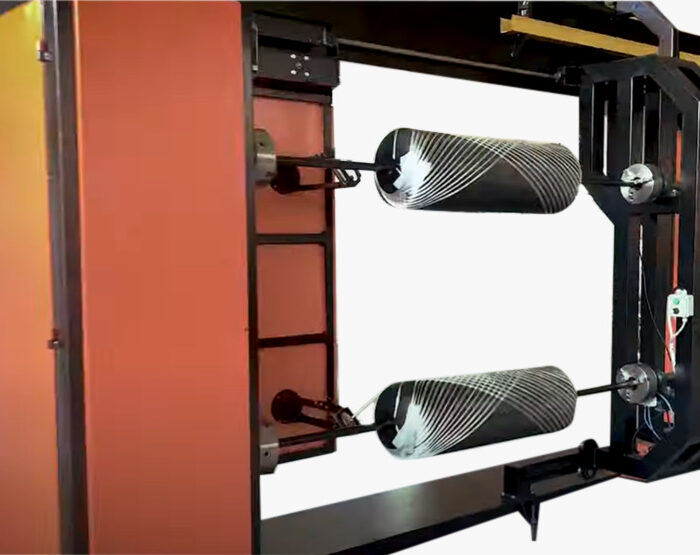

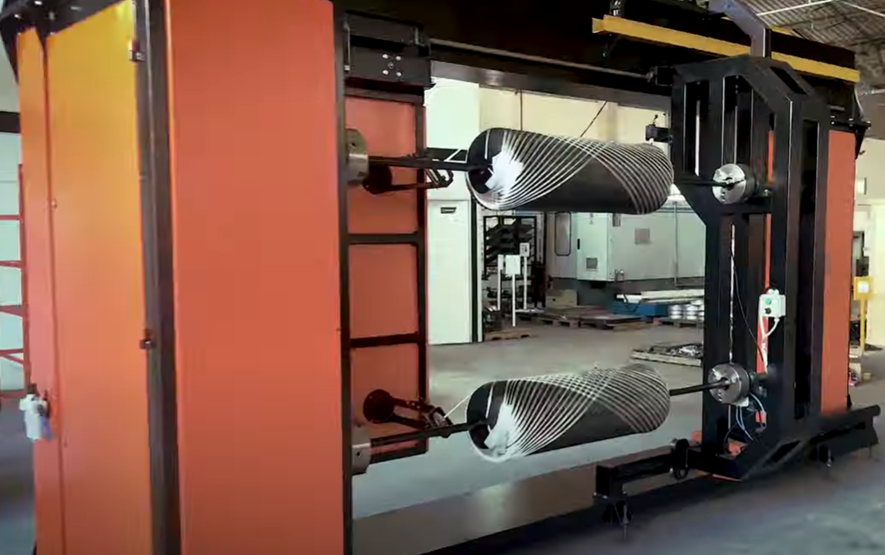

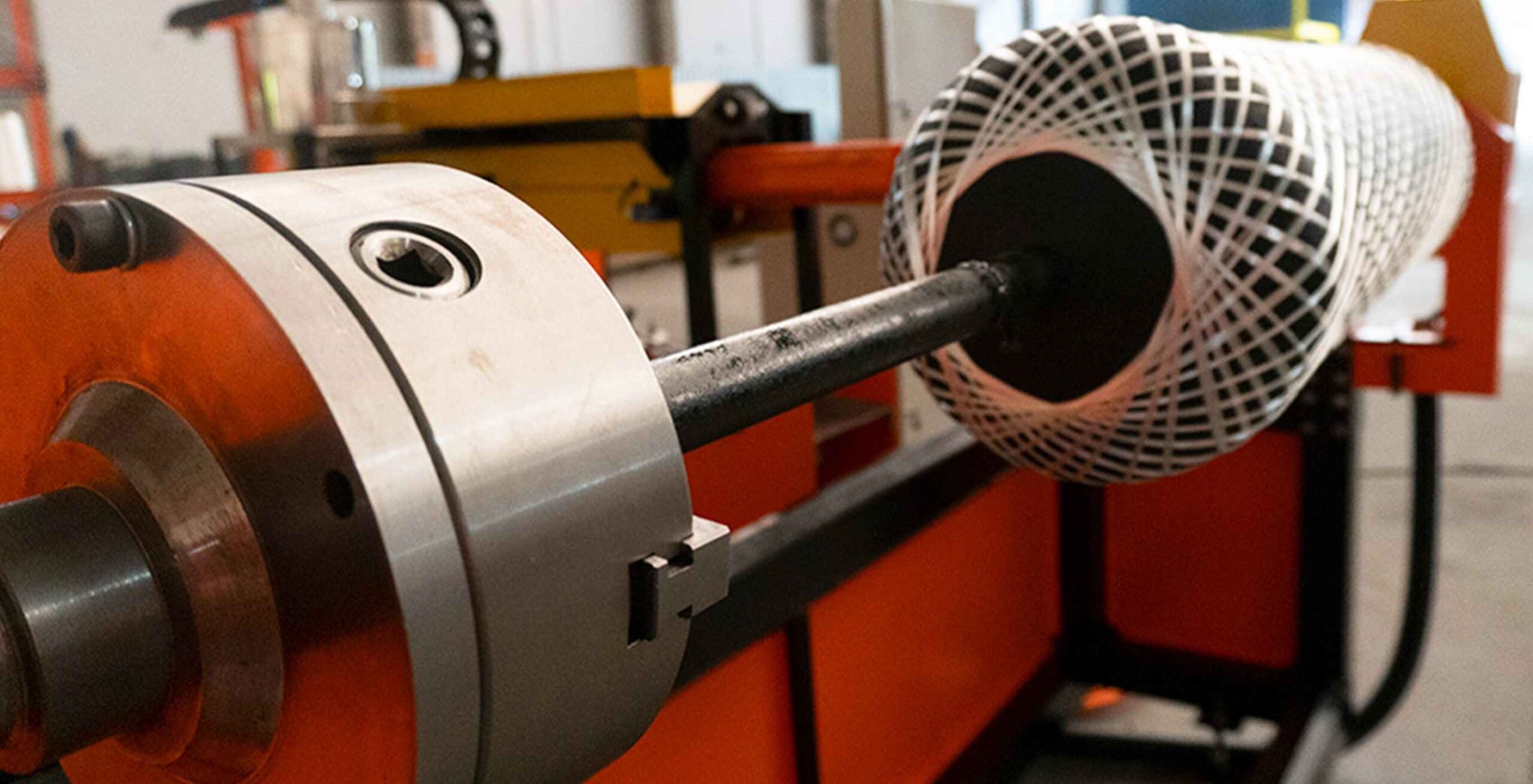

Our filament winders are made to make your life as easy as possible. Using CNC controlled winders, very precise winding of fibers around mandrels of various shapes is guaranteed. This consistency creates durable and high-quality products like pipes, tanks, poles, and tubes. Whether you’re producing large or small composite items, our filament winding systems provide great performance and flexibility.

Uses of Our Filament Winders

Our filament winding machines are ideal for creating a wide range of composite products, including poles, pipes, tanks, and cylinders. The system uses multiple spindles, allowing for the simultaneous production of several items, which maximizes efficiency. Whether you need to produce standard-sized tubes or custom composite structures, our filament winders always deliver consistent results.

Key Features

- CNC controlled winders

- Siemens software integration

- Flexible production capabilities

- High precision

Customization Options

- Number of spindles for simultaneous production

- Axes for precise winding configurations

- Product diameter and length capabilities

- Weight capacity for heavy composite products

- Wet winding with resin baths or pre-impregnated fiber winding (prepregs)

Why us?

Our filament winders are a perfect fit for manufacturers who seek high performance in their production. Those who work with us can expect great machine accuracy, CNC-driven machines, reliability, and customizability, such as diameter, number of spindles, length of the product, or weight of the product. Using our systems can improve production times and maintain exceptional product quality.

Conclusion

Our filament winders are the solution for your new line. From winding small tubes to large tanks, our machine delivers consistent and efficient results. These key features make sure you can make the best composite products and don’t have to worry about product inconsistencies. If this sounds like the right fit for your new composite production line, feel free to reach out and discuss the perfect fit for you.

Filament winding process

Let's work together

Fill in this contactform and we will contact you!