Resin impregnation systems

Resin impregnation systems

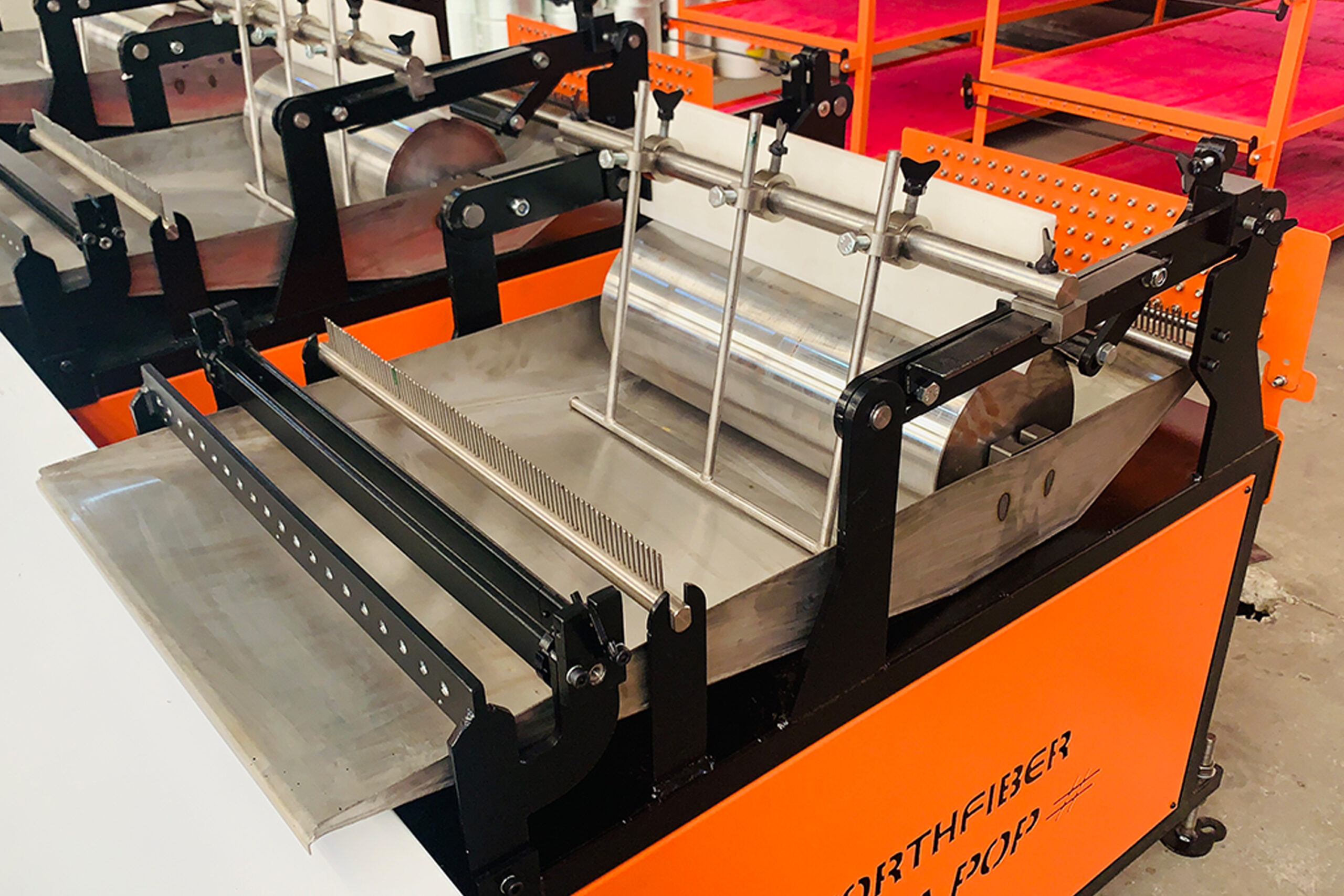

Our resin impregnation system provides an efficient solution for impregnating fibers with a mixed resin, ensuring durability and consistency across the finished composite materials. This system is designed to improve production by utilizing minimal fiber tension and easy maintenance, resulting in strong, high-quality composite products with reliable performance. If you’re interested, feel free to reach out to learn more about how we can support your operations.

Our resin impregnation system

Our system uses a high-quality resin tray designed with Composite Machinery standards. Special squeeze bars ensure that every fiber strand is evenly coated. Together with the ready-mixed resin, these squeeze bars help achieve the optimal fiber volume fraction, creating a composite product ready for curing.

One of the most essential parts of the impregnation process is the temperature of the resin, which is regulated by heated water below the resin tray. To achieve maximum consistency, the temperature is controlled by a PLC system, which ensures an optimal water and resin temperature. The system accommodates strands like fiberglass, carbon, or basalt with low added tension and can handle different resins, like polyester, epoxy, and phenyl ester.

Key Features

- Optimized Fiber Volume Fraction (FVF)

- Adjustable squeeze bars

- Water-heated bath with PLC-controlled temperature

- Low tension design

- Compatible with various resin types

- User-friendly installation

- Easy maintenance

The perfect resin impregnation system for your new line?

This system is ideal for applications where high-quality fiber impregnation is essential. It delivers reliable, high-strength composite products with minimal void content and maximal consistency. The controlled impregnation process ensures composite products meet high standards, while easy setup and cleaning reduce downtime and maintenance demands.

Conclusion

The resin impregnation system is ideal for manufacturers looking for a durable composite product. Advanced features like dual drums and uniform resin distribution let the system achieve high-speed production while producing top-quality products. Whether for aerospace, automotive, or industrial use, this system ensures consistent quality, strength, and efficiency across composite products.

Let's work together

Fill in this contactform and we will contact you!