Pultrusion

Pultrusion technology

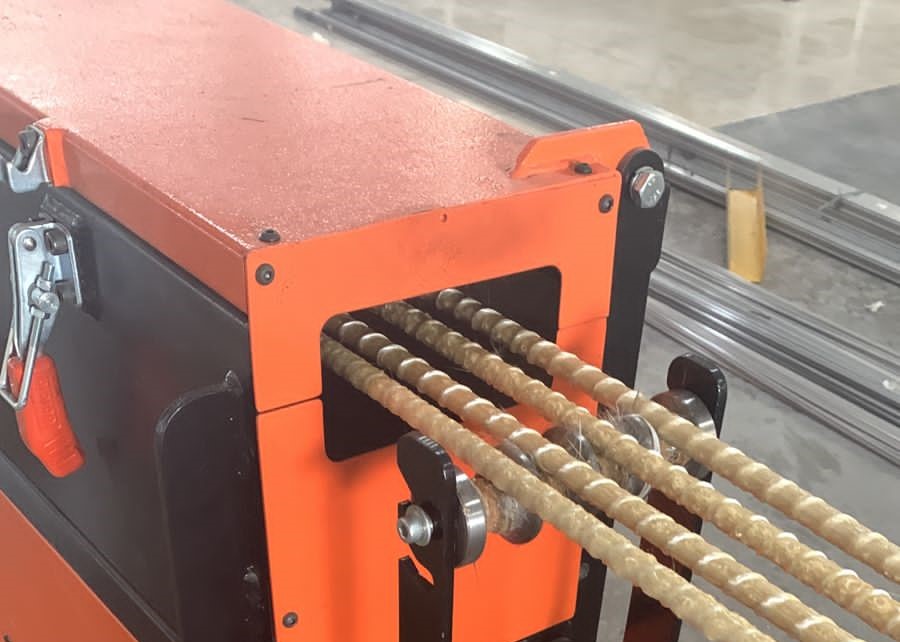

The pultrusion process is one of the technologies in the production of composites, which is recognized for making powerful, lightweight composite products. The process involves the continuous pulling of reinforcing fibers (such as glass, carbon, or basalt) through a resin bath for impregnation, followed by a heated shaping die that cures the fibers into a solid, uniform profile The form of the product is created by pulling the impregnated fiber through a shaping die and then curing the impregnated fibers, which results in a strong, consistent unidirectional profile. These cured fibers are famous for their efficiency, precision, and consistency. Pultrusion delivers durable, corrosion-resistant composite products, such as tubes, ideal for demanding applications.

Our company leverages the latest advancements in software, real-time product measurement systems, and automation to ensure unparalleled quality and performance, setting the industry standard for precision and reliability in composite manufacturing.

What Is Pultrusion

Pultrusion is a special manufacturing process in the production of composites. Reinforcing fibers are pulled through a resin bath, impregnating them with a tailored resin formulation. The impregnated fibers are pulled through a shaping die that cures them into a solid, consistent cross-sectioned profile. This method ensures exceptional strength-to-weight ratios, dimensional accuracy, and repeatability.

Our state-of-the-art pultrusion systems integrate advanced software for process control, precise product measurements, and automated workflows, optimizing efficiency and ensuring superior quality in every composite tube produced for industries like the building construction industry and infrastructure.

The Advantages Of Pultrusion Technology

Pultrusion offers unmatched efficiency, minimizing material waste and reducing production costs. The resulting composite tubes are lightweight yet capable of withstanding significant loads, making them ideal for structural and high-performance applications. Their corrosion resistance and durability ensure longevity, even in harsh environments, providing cost-effective solutions for infrastructure, automotive, aerospace, and construction sectors. By incorporating cutting-edge automation and real-time monitoring, our pultrusion process delivers consistent, high-quality profiles that meet stringent industry standards, enhancing reliability and performance across diverse applications.

Conclusion

Our company is committed to driving innovation in composite manufacturing to address global challenges like climate change, energy efficiency, water management, urbanization, and the pursuit of a better future. By utilizing the most advanced pultrusion technology—powered by sophisticated software, precise measurement systems, and automation—we deliver sustainable, high-performance composite tubes. Our dedication to research and development ensures continuous improvement of our processes and products, fostering strong client partnerships and contributing to a more sustainable future through environmentally responsible manufacturing practices.

Pultrusion process

Let's work together

Fill in this contactform and we will contact you!